Enterprise resource planning systems are the backbone of modern business, orchestrating a symphony of interconnected processes that drive efficiency and growth. This comprehensive exploration delves into the multifaceted world of ERP, revealing how these integrated software solutions transform raw data into actionable insights, empowering organizations to navigate complex operations with unprecedented clarity and control.

From its foundational purpose of streamlining operations to its sophisticated evolution and diverse module structure, this document provides a deep dive into the core of what makes ERP systems indispensable. We will examine the strategic advantages and potential challenges of adoption, the technological underpinnings that support these powerful platforms, and their profound impact across various industries and business sizes. Furthermore, we will Artikel the essential steps for selecting and implementing an ERP solution effectively, culminating in an analysis of the future trends shaping this dynamic field.

Defining the Fundamental Purpose of Enterprise Resource Planning Systems in Streamlining Business Operations

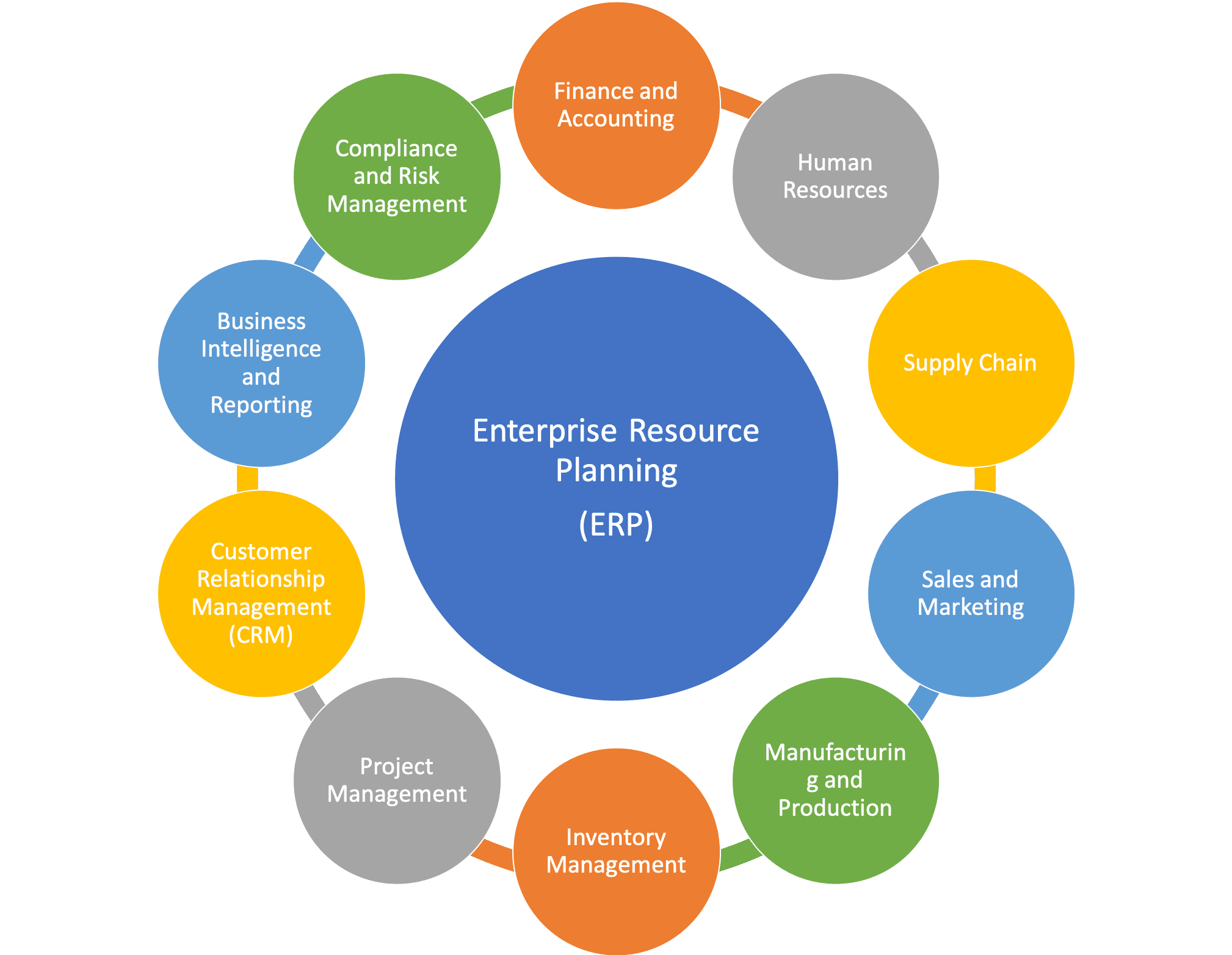

Enterprise Resource Planning (ERP) systems are the backbone of modern business management, designed to integrate and streamline a company’s core processes into a single, unified platform. At its heart, the fundamental purpose of an ERP system is to break down departmental silos and create a holistic view of business operations, thereby enhancing efficiency, reducing costs, and improving decision-making. This integration allows for the seamless flow of information across various functions, from finance and human resources to supply chain and customer relationship management, fostering a more agile and responsive organization.The core functionalities and objectives of an ERP system revolve around providing a centralized database and a suite of integrated applications that manage and automate key business activities.

These systems aim to standardize business processes, improve data accuracy and accessibility, and provide real-time insights into operational performance. By consolidating data from disparate sources, ERPs eliminate redundant data entry, minimize errors, and ensure that all stakeholders are working with the most current and accurate information. The ultimate goal is to achieve operational excellence by optimizing resource allocation, improving productivity, and driving profitability.Organizations realize a multitude of primary benefits from implementing integrated software solutions for managing their core processes.

These benefits extend across various facets of the business, leading to significant improvements in overall performance and competitiveness.

- Enhanced Efficiency and Productivity: Automating routine tasks and streamlining workflows frees up employee time, allowing them to focus on more strategic initiatives. This leads to a noticeable increase in overall productivity and operational efficiency.

- Improved Data Accuracy and Visibility: A single source of truth for all business data reduces errors associated with manual data entry and reconciliation. Real-time access to accurate information empowers better decision-making and forecasting.

- Cost Reduction: By optimizing inventory levels, reducing waste, improving procurement processes, and streamlining operations, ERP systems can lead to substantial cost savings.

- Better Decision-Making: With integrated data and comprehensive reporting capabilities, management gains a clear, real-time view of business performance, enabling more informed and strategic decisions.

- Increased Customer Satisfaction: Streamlined order processing, improved inventory management, and faster response times contribute to a better customer experience.

- Regulatory Compliance: ERP systems can help organizations meet industry-specific regulations and reporting requirements by standardizing processes and maintaining accurate audit trails.

The introduction of ERP systems significantly impacts several key business areas, transforming how these departments function and interact.

Impact on Core Business Areas

The implementation of an ERP system reverberates through critical business functions, creating a more cohesive and efficient operational landscape.

Finance and Accounting

The finance department experiences a profound transformation with ERP integration. Core functionalities include automated accounts payable and receivable, general ledger management, budgeting, and financial reporting. The system ensures real-time financial data, simplifies reconciliation processes, and provides robust tools for financial analysis and forecasting. This leads to improved cash flow management, enhanced financial controls, and more accurate financial statements, crucial for compliance and investor relations.

Human Resources Management

In human resources, ERP systems streamline critical functions such as payroll processing, employee data management, recruitment, onboarding, and performance tracking. Centralizing employee information reduces administrative burden and ensures data consistency. Advanced modules can also support workforce planning, talent management, and compliance with labor laws, contributing to a more engaged and productive workforce.

Supply Chain Management

The supply chain is one of the most heavily impacted areas. ERPs integrate functions like procurement, inventory management, warehousing, logistics, and production planning. This allows for better demand forecasting, optimized inventory levels, reduced lead times, and improved supplier relationships. Real-time visibility into the supply chain helps in proactively addressing disruptions and ensuring timely delivery of goods and services, directly impacting customer satisfaction and operational costs.

Sales and Customer Relationship Management (CRM)

While CRM is often a separate module or integrated system, ERPs provide the foundational data that powers sales and customer interactions. Integration ensures that sales teams have access to up-to-date product availability, pricing, and customer history. Order processing is streamlined, from quotation to fulfillment, leading to faster order cycles and improved customer service.

Conceptual Model of ERP Module Communication

The power of an ERP system lies in its ability to create a unified operational view through the seamless communication and data sharing between its various modules. This is conceptually modeled as a central nervous system for the business, where each module represents a specific organ or function, all connected to a shared central database.Imagine a central database as the core of the system.

When a sales order is entered into the sales module, this information is immediately accessible to other relevant modules. For instance, the inventory management module can check stock levels and update them accordingly. If inventory is low, it can trigger a request to the procurement module to order more raw materials or finished goods. Simultaneously, the finance module receives information about the sale, which impacts accounts receivable and revenue recognition.The human resources module might be updated with information related to new employee onboarding initiated through a recruitment process managed within the HR function, impacting payroll and employee records.

Production planning uses sales forecasts and inventory data to schedule manufacturing runs. The supply chain module tracks the movement of goods, from raw material acquisition to finished product delivery, feeding information back into inventory and finance.This interconnectedness ensures that decisions made in one department are informed by real-time data from others, eliminating the need for manual data transfer and reducing the risk of errors.

The conceptual model is one of a dynamic, interconnected network, where data flows freely and instantaneously between modules, creating a single, consistent, and comprehensive view of the entire business operation.

“An ERP system acts as the central nervous system of an organization, enabling real-time data flow and synchronized operations across all departments.”

Exploring the Historical Evolution of Enterprise Resource Planning Software

The journey of Enterprise Resource Planning (ERP) systems is a fascinating narrative of technological innovation and evolving business needs. What began as specialized tools for manufacturing has blossomed into comprehensive, integrated platforms that manage nearly every facet of an organization. Understanding this evolution provides crucial context for appreciating the power and complexity of modern ERP.The genesis of ERP systems can be traced back to the mid-20th century, specifically to the development of Materials Requirement Planning (MRP).

This foundational concept emerged from the manufacturing sector’s pressing need to manage inventory efficiently and schedule production effectively. Early MRP systems focused on calculating the raw materials and components required for manufacturing a product, based on a bill of materials, inventory levels, and production schedules. The primary goal was to ensure that the right materials were available at the right time, thereby minimizing stockouts and reducing excess inventory.

This marked a significant departure from ad-hoc inventory management, introducing a systematic, data-driven approach to production planning.

The Expansion Beyond Manufacturing

As MRP systems matured, their limitations became apparent. They were largely siloed within the manufacturing department, failing to address other critical business functions like finance, human resources, or sales. This fragmentation led to inefficiencies, data inconsistencies, and a lack of holistic business visibility. The driving force behind the expansion of ERP capabilities was a combination of technological advancements and escalating market pressures.

The advent of more powerful computing hardware and sophisticated software development methodologies made it feasible to integrate disparate business processes. Furthermore, businesses recognized the competitive advantage of having a unified view of their operations. Companies began demanding systems that could extend beyond the factory floor, connecting production planning with financial accounting, order management, and customer relationship management. This desire for integration and comprehensive business management laid the groundwork for the evolution from MRP to MRP II (Manufacturing Resource Planning) and eventually to ERP.

Key Milestones and Paradigm Shifts

The evolution of ERP has been punctuated by several key milestones and paradigm shifts that have dramatically reshaped its capabilities and accessibility.

- MRP to MRP II: The transition from MRP to MRP II in the 1970s and 1980s was a crucial step. MRP II expanded the scope beyond just materials to include capacity planning, scheduling, and shop floor control, offering a more comprehensive view of the manufacturing process.

- The Rise of Integrated ERP: In the 1990s, the concept of a single, integrated system that encompassed all core business functions – finance, human resources, manufacturing, supply chain, services, procurement, and more – gained traction. This era saw the emergence of major ERP vendors offering comprehensive suites.

- Client-Server Architectures: The shift from mainframe-based systems to client-server architectures in the 1990s made ERP systems more accessible and flexible. This allowed for better scalability and reduced reliance on expensive, centralized hardware.

- The Internet and Web-Based ERP: The widespread adoption of the internet and the World Wide Web in the late 1990s and early 2000s paved the way for web-enabled ERP solutions. This improved accessibility and facilitated collaboration across geographically dispersed teams.

- Service-Oriented Architecture (SOA) and Middleware: The early 2000s saw the adoption of SOA, which allowed different software components to communicate with each other more easily. Middleware solutions became essential for integrating ERP with other specialized business applications.

- Cloud Computing and SaaS ERP: The most significant recent paradigm shift has been the move to cloud-based ERP, often delivered as Software as a Service (SaaS). This has democratized ERP, making it more affordable and easier to deploy and manage, especially for small and medium-sized businesses. Cloud ERP offers inherent scalability, automatic updates, and reduced IT infrastructure costs.

- The Advent of Intelligent ERP: Today’s ERP systems are increasingly incorporating advanced technologies like artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT). This “intelligent ERP” aims to provide predictive insights, automate complex tasks, and offer proactive recommendations, transforming ERP from a transactional system to a strategic business enabler.

Comparing Early ERP with Modern Platforms

The chasm between early ERP systems and today’s sophisticated platforms is vast, reflecting decades of technological advancement and a deeper understanding of business requirements.

| Characteristic | Early ERP Systems | Modern, Agile, and Intelligent ERP Platforms |

|---|---|---|

| Scope and Integration | Primarily focused on manufacturing and finance; integration was often challenging and limited. | Comprehensive, end-to-end integration across all business functions; holistic view of the organization. |

| Architecture | Monolithic, often mainframe-based; later moved to client-server. | Modular, cloud-native, microservices-based, highly scalable and flexible. |

| User Interface (UI) and User Experience (UX) | Complex, text-heavy interfaces; difficult to navigate and use. | Intuitive, user-friendly, often mobile-first interfaces with personalized dashboards and role-based access. |

| Data Analysis and Insights | Basic reporting capabilities; data was often static and retrospective. | Advanced analytics, AI-powered insights, predictive modeling, real-time dashboards, and embedded business intelligence. |

| Customization and Agility | Rigid and difficult to customize; upgrades were costly and disruptive. | Highly configurable, adaptable to changing business needs, rapid deployment, continuous updates through cloud. |

| Deployment and Management | On-premises, requiring significant IT infrastructure and expertise. | Cloud-based (SaaS), managed by vendors, reducing IT burden and offering faster time-to-value. |

| Intelligence and Automation | Primarily transactional; limited automation. | Embedded AI and ML for process automation, predictive maintenance, fraud detection, and intelligent decision-making. |

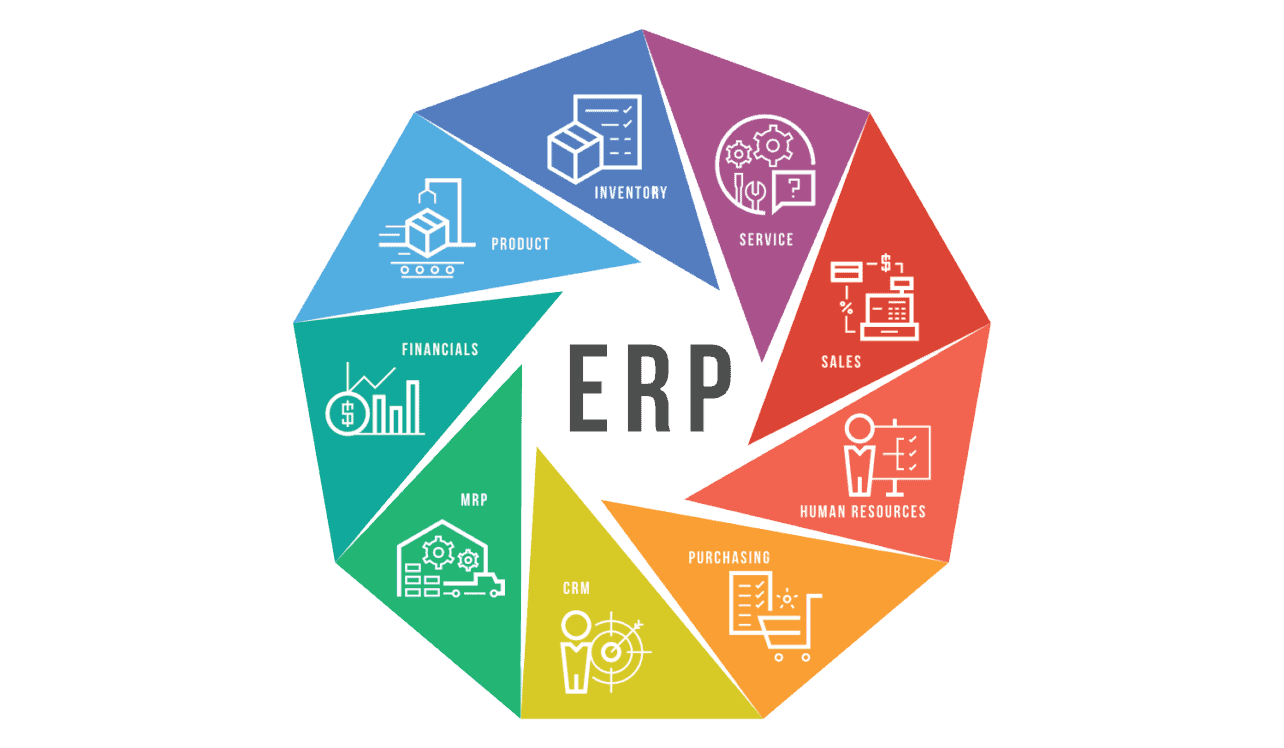

Illustrate the diverse modules commonly found within an enterprise resource planning suite and their interconnectedness.

Enterprise Resource Planning (ERP) systems are sophisticated software solutions designed to integrate and manage core business processes across various departments. A typical ERP suite is not a monolithic entity but rather a collection of specialized modules, each addressing a distinct functional area of the business. These modules work in concert, sharing data and automating workflows to provide a unified view of operations and enhance overall efficiency.

Understanding these modules and their interconnectedness is key to appreciating the power and utility of an ERP system.The strength of an ERP lies in its ability to break down data silos and foster seamless collaboration between departments. By centralizing information and standardizing processes, ERPs enable organizations to operate more intelligently, make better-informed decisions, and respond more agilely to market changes.

The interconnectedness ensures that an action taken in one module can automatically trigger relevant updates and actions in others, creating a virtuous cycle of efficiency and accuracy.

Core ERP Modules and Their Functions

A comprehensive ERP system typically encompasses a range of modules, each designed to manage specific business functions. These modules are the building blocks of the ERP, and their integration is what transforms disparate business activities into a cohesive operational framework.

- Finance and Accounting (F&A): This is often considered the backbone of any ERP system. Its functions include general ledger management, accounts payable and receivable, budgeting, financial reporting, asset management, and cash flow management. By automating financial processes, F&A modules ensure accurate record-keeping, compliance with regulations, and provide critical insights into the financial health of the organization.

- Human Capital Management (HCM): Also known as Human Resources (HR) modules, this area manages all aspects of an employee’s lifecycle. Key functions include payroll processing, benefits administration, time and attendance tracking, recruitment and onboarding, performance management, and employee data management. HCM modules streamline HR operations, improve employee satisfaction, and ensure compliance with labor laws.

- Customer Relationship Management (CRM): CRM modules focus on managing all customer interactions and data throughout the customer lifecycle. This includes sales force automation, marketing campaign management, customer service and support, contact management, and lead tracking. By providing a 360-degree view of the customer, CRM enables better customer engagement, increased sales, and improved customer retention.

- Supply Chain Management (SCM): SCM modules oversee the entire flow of goods and services, from procurement of raw materials to delivery of finished products to the customer. This encompasses inventory management, warehouse management, procurement, order fulfillment, logistics, and demand planning. Effective SCM modules reduce costs, improve efficiency, and ensure timely delivery, thereby enhancing customer satisfaction.

- Manufacturing/Production: For businesses involved in manufacturing, this module is crucial. It handles production planning, material requirements planning (MRP), bill of materials (BOM), shop floor control, quality management, and capacity planning. It ensures efficient production scheduling, optimal resource utilization, and adherence to quality standards.

- Procurement: This module manages the purchasing of goods and services. It includes purchase order creation, vendor management, contract management, and spend analysis. Streamlining procurement reduces costs, ensures timely acquisition of necessary resources, and helps in building strong supplier relationships.

- Sales and Distribution: This module manages the entire sales process, from quoting and order entry to invoicing and shipping. It includes sales order processing, pricing, credit management, and delivery management. It ensures efficient order fulfillment and accurate billing.

Interconnectedness of ERP Modules: A Conceptual Flow, Enterprise resource planning

The true power of an ERP system is realized through the seamless flow of data and automated processes between these modules. This interconnectedness eliminates redundant data entry, reduces errors, and provides real-time visibility across the organization.Imagine a conceptual diagram where modules are represented as interconnected nodes. Data flows between these nodes, illustrating how a single event can trigger a cascade of actions.

For instance, when a sales representative creates a customer order in the CRM module, this event doesn’t just stay within CRM. It immediately triggers a series of integrated processes:

Scenario: Processing a Customer Order

- Sales Order Creation (CRM): A customer places an order via a sales representative or an online portal. The CRM module captures all order details: customer information, products, quantities, pricing, and delivery date.

- Inventory Check and Allocation (SCM): The moment the sales order is finalized in CRM, the system automatically checks inventory levels in the Supply Chain Management module. If the stock is available, it’s allocated to this order, reducing the available quantity. If not, it might trigger a backorder notification or a production request.

- Production Order (Manufacturing/Production): If the item is not in stock and needs to be manufactured, the system can automatically generate a production order in the Manufacturing module based on the sales order requirements and BOM.

- Procurement Trigger (Procurement): If raw materials are needed for manufacturing, the system might automatically generate purchase requisitions in the Procurement module to order those materials from suppliers, based on the production plan and current inventory.

- Financial Posting (F&A): Once the order is ready to be shipped or has been shipped, the Sales and Distribution module signals the Finance and Accounting module. This triggers the creation of an invoice for the customer and a corresponding entry in accounts receivable. The cost of goods sold is also calculated and posted.

- Warehouse Operations (SCM): The Sales and Distribution module also informs the Warehouse Management component of SCM, generating a pick list for warehouse staff. Once the goods are picked and packed, the system updates the inventory levels again, reflecting the shipment.

- Payroll Impact (HCM): If the order fulfillment involves overtime for warehouse staff, this information would be captured in the time and attendance system, eventually impacting payroll processed by the HCM module.

This end-to-end process, initiated by a single customer order, demonstrates how different ERP modules are not isolated islands but rather interconnected components of a unified system. The data entered once in CRM flows through SCM, Manufacturing, Procurement, F&A, and Sales & Distribution, ensuring consistency, accuracy, and efficiency at every step. This integration allows businesses to gain real-time visibility into their operations, from initial customer engagement to final financial settlement.

Examining the Strategic Advantages and Potential Challenges of Enterprise Resource Planning Adoption

Implementing an Enterprise Resource Planning (ERP) system represents a significant strategic undertaking for any organization. While the promise of streamlined operations and enhanced efficiency is compelling, the journey is not without its complexities. Understanding both the profound benefits and the inherent challenges is crucial for successful adoption and for maximizing the return on this substantial investment.

The strategic advantages of a well-implemented ERP system are multifaceted, touching upon core business functions and driving competitive advantage. These systems act as a central nervous system for an organization, integrating disparate data and processes into a unified platform. This integration fosters a holistic view of the business, enabling more informed and agile decision-making.

Compelling Business Cases for ERP Investment

The justification for investing in an ERP system often hinges on its ability to deliver tangible improvements across several critical business areas. The core value proposition lies in its capacity to consolidate information, eliminate redundancies, and provide a single source of truth, which directly impacts operational efficiency and strategic foresight.

One of the most significant business cases is the dramatic improvement in data accuracy. Traditional, siloed systems are prone to manual data entry errors, inconsistencies, and outdated information. An ERP system enforces standardized data input and validation rules, ensuring that all departments are working with the same, reliable data. This accuracy is fundamental for accurate reporting and analysis.

This enhanced data accuracy directly fuels better decision-making. With real-time, accurate data readily available, managers and executives can gain deeper insights into performance metrics, identify trends, and forecast future outcomes with greater confidence. For instance, a sales team can accurately track inventory levels to avoid promising products that are out of stock, while the finance department can generate precise financial statements for immediate analysis.

This agility in decision-making allows businesses to respond more effectively to market changes and seize opportunities.

Furthermore, ERP systems are instrumental in ensuring robust regulatory compliance. Many industries are subject to stringent regulations concerning financial reporting, data privacy, and operational standards. An ERP system can be configured to enforce compliance protocols, automate reporting for regulatory bodies, and maintain audit trails. For example, in the pharmaceutical industry, an ERP can track lot numbers, expiry dates, and manufacturing processes, ensuring adherence to strict FDA regulations.

Similarly, in the financial sector, it can help comply with Sarbanes-Oxley (SOX) requirements by providing clear audit trails and segregation of duties.

Beyond these core areas, ERPs contribute to improved supply chain management, optimized production planning, enhanced customer relationship management, and more efficient human resource management. The cumulative effect of these improvements often leads to significant cost savings and increased profitability, presenting a strong business case for the initial investment.

Common Pitfalls and Obstacles in ERP Implementation

Despite the clear advantages, ERP implementations are notoriously complex and fraught with potential challenges. Organizations often underestimate the scope of these projects, leading to costly delays and failed initiatives. Proactive identification and mitigation of these common pitfalls are essential for a successful rollout.

A primary obstacle is change management. Employees are often accustomed to existing processes and tools, and resistance to change can be a significant hurdle. Without proper communication, training, and buy-in from all levels of the organization, users may be reluctant to adopt the new system, leading to workarounds or outright rejection of the ERP. This resistance can undermine the intended benefits of the system.

Data migration is another critical and often underestimated challenge. Moving data from legacy systems to the new ERP can be a complex and time-consuming process. Inaccurate, incomplete, or improperly formatted data can lead to errors in the new system, negating the benefits of improved data accuracy. Thorough data cleansing and validation are paramount before migration.

User adoption is intrinsically linked to change management and data quality. If users find the system difficult to use, if it doesn’t align with their daily tasks, or if they haven’t been adequately trained, adoption rates will suffer. This can result in underutilization of the system’s capabilities, leading to a failure to achieve the desired ROI.

Other common issues include inadequate project planning and scope creep, insufficient executive sponsorship, unrealistic timelines, and a lack of clear business objectives for the ERP implementation. Overlooking any of these aspects can derail even the best-intentioned ERP project.

Critical Success Factors for ERP Rollout

To navigate the complexities of ERP implementation and ensure a smooth and effective rollout, several critical success factors must be prioritized. These factors are not merely recommendations but are foundational to achieving the intended benefits of the system.

The most crucial element is strong executive sponsorship. Without active and visible support from senior leadership, an ERP project is unlikely to gain the necessary resources, overcome organizational resistance, or maintain momentum. Executives must champion the project, communicate its importance, and actively participate in key decisions.

Thorough planning is another non-negotiable success factor. This includes defining clear business objectives, establishing realistic timelines and budgets, conducting a comprehensive business process analysis, and developing a detailed implementation roadmap. A phased approach, often starting with core modules, can also mitigate risk.

Other critical success factors include:

- Forming a dedicated and skilled project team with representatives from all key business functions.

- Selecting the right ERP solution that aligns with the organization’s specific needs and future growth plans.

- Implementing a robust change management strategy that includes clear communication, comprehensive training, and ongoing user support.

- Conducting thorough testing of the system before go-live to identify and resolve any issues.

- Establishing clear key performance indicators (KPIs) to measure the success of the implementation.

Framework for Evaluating ERP System Return on Investment (ROI)

Quantifying the return on investment (ROI) of an ERP system is essential to justify the initial expenditure and to demonstrate its ongoing value to the organization. A well-defined framework ensures that the assessment is comprehensive and considers both tangible and intangible benefits.

The calculation of ERP ROI typically involves comparing the total cost of ownership with the realized benefits over a specific period. The formula is generally represented as:

ROI = ((Total Benefits – Total Costs) / Total Costs) – 100%

Key metrics and considerations for assessing its long-term value include:

- Tangible Benefits: These are quantifiable cost savings and revenue enhancements. Examples include:

- Reduction in operational costs (e.g., reduced inventory carrying costs due to better forecasting, lower administrative expenses through automation).

- Improved labor productivity (e.g., less time spent on manual data entry, faster order processing).

- Increased sales revenue (e.g., through better customer service, improved product availability).

- Reduced waste and scrap in manufacturing processes.

- Lower IT maintenance costs by consolidating disparate systems.

- Intangible Benefits: While harder to quantify directly, these benefits are crucial for long-term success and include:

- Enhanced decision-making capabilities due to better data visibility.

- Improved customer satisfaction and loyalty.

- Increased agility and responsiveness to market changes.

- Better regulatory compliance and reduced risk of fines.

- Improved employee morale and engagement through more efficient processes.

- Total Costs: This includes all expenses associated with the ERP system, such as:

- Software licensing or subscription fees.

- Hardware and infrastructure costs.

- Implementation and customization services.

- Training and change management expenses.

- Ongoing maintenance, support, and upgrade costs.

A comprehensive ROI analysis should consider a realistic timeframe, typically three to five years, to capture the full spectrum of benefits. It’s also important to regularly review and update the ROI calculation as the system matures and new benefits emerge.

Describing the Technological Underpinnings and Architectural Considerations of Modern Enterprise Resource Planning Systems

Modern Enterprise Resource Planning (ERP) systems are sophisticated technological marvels, built upon a foundation of interconnected components designed to manage and integrate the core business processes of an organization. Their architecture is crucial for ensuring scalability, reliability, and the seamless flow of information across various departments. Understanding these underlying technologies is key to appreciating how ERP systems achieve their goal of streamlining operations and providing a unified view of the business.

This involves a careful consideration of how the software is deployed, the core infrastructure that supports it, and the mechanisms that allow it to communicate with other essential business tools.The design of an ERP system is not a one-size-fits-all proposition. The underlying technology and architectural choices are heavily influenced by the specific needs and resources of the organization. This includes how the software is physically or virtually installed, the underlying hardware and software stack, and how it is maintained and updated.

Furthermore, the ability of an ERP system to function effectively hinges on its capacity to integrate with a multitude of other applications that businesses rely on daily, from customer relationship management (CRM) tools to specialized manufacturing execution systems. This intricate web of technology ensures that data is not siloed but rather shared and utilized to its fullest potential, driving efficiency and informed decision-making.

Deployment Options for ERP Software

The way an ERP system is deployed significantly impacts its cost, accessibility, maintenance, and overall flexibility. Businesses today have a spectrum of choices, each with distinct advantages and disadvantages that must be carefully weighed against their operational requirements and strategic goals. These options range from traditional on-premises installations to cutting-edge cloud-based solutions, with a popular middle ground in hybrid models.

- On-Premises Deployment: In this traditional model, the ERP software is installed and runs on servers physically located within the organization’s own data center. The business is responsible for purchasing, installing, configuring, and maintaining all the necessary hardware, software licenses, and infrastructure.

- Implications: This offers maximum control over data and security, as it resides entirely within the company’s network. It can be highly customizable to meet unique business processes.

However, it requires significant upfront investment in hardware and IT personnel, and ongoing costs for maintenance, upgrades, and energy consumption. Scalability can also be a challenge, requiring further hardware purchases to expand.

- Implications: This offers maximum control over data and security, as it resides entirely within the company’s network. It can be highly customizable to meet unique business processes.

- Cloud-Based Deployment: Also known as Software-as-a-Service (SaaS) ERP, this model involves the ERP software being hosted and managed by a third-party vendor on their servers and accessed by users over the internet.

- Implications: This model typically involves a subscription-based pricing structure, reducing upfront capital expenditure. It offers greater scalability and flexibility, as resources can be easily adjusted based on demand.

The vendor handles all maintenance, updates, and infrastructure management, freeing up internal IT resources. However, it can mean less direct control over data security and customization options might be more limited compared to on-premises solutions. Businesses are also dependent on internet connectivity.

- Implications: This model typically involves a subscription-based pricing structure, reducing upfront capital expenditure. It offers greater scalability and flexibility, as resources can be easily adjusted based on demand.

- Hybrid Deployment: This approach combines elements of both on-premises and cloud-based deployments. Certain ERP modules or data might be hosted on-premises for security or performance reasons, while others are deployed in the cloud for scalability and accessibility.

- Implications: A hybrid model allows businesses to leverage the benefits of both worlds. For instance, sensitive financial data could remain on-premises, while customer-facing modules like CRM are in the cloud.

This offers a balance between control, cost, and flexibility. However, managing a hybrid environment can be more complex, requiring careful integration and coordination between the on-premises and cloud components.

- Implications: A hybrid model allows businesses to leverage the benefits of both worlds. For instance, sensitive financial data could remain on-premises, while customer-facing modules like CRM are in the cloud.

The Role of Core Infrastructure Components

The robust functioning of an ERP system relies on a sophisticated interplay of several key technological components. These elements work in concert to process transactions, manage data, and deliver the functionality that businesses depend on. Without these foundational layers, the complex operations of an ERP system would be impossible to sustain.

- Databases: At the heart of any ERP system lies its database, which serves as the central repository for all business data. This includes everything from customer information and inventory levels to financial transactions and employee records. Modern ERP systems typically utilize relational databases (like Oracle, SQL Server, or PostgreSQL) or, increasingly, NoSQL databases for specific use cases, ensuring data integrity, consistency, and efficient retrieval.

The database design and optimization are critical for performance.

- Application Servers: These servers host the ERP application’s business logic and processes. When a user interacts with the ERP system, their requests are processed by the application server, which then retrieves or updates data from the database and returns the results. Application servers manage user sessions, execute workflows, and enforce business rules, acting as the engine that drives the ERP’s functionality.

- Middleware: Middleware acts as a crucial intermediary, facilitating communication and data exchange between different components of the ERP system and between the ERP and other external applications. It can handle tasks such as data transformation, message queuing, and protocol conversion, ensuring that disparate systems can interact seamlessly. This is particularly important in complex, integrated environments.

System Integration Capabilities

The true power of an ERP system is amplified when it can seamlessly communicate and exchange data with other critical business applications. This integration capability is paramount for creating a unified, end-to-end view of business operations and avoiding data silos. Modern ERP systems are designed with this in mind, employing various mechanisms to achieve interoperability.The ability of an ERP system to connect with other software solutions is no longer a luxury but a necessity.

Whether it’s linking with a customer relationship management (CRM) platform to share sales leads and customer history, integrating with an e-commerce website to manage orders and inventory, or connecting with supply chain management (SCM) tools for real-time logistics updates, robust integration capabilities are essential.The primary methods for achieving this integration include:

- APIs (Application Programming Interfaces): APIs are sets of rules and protocols that allow different software applications to communicate with each other. ERP vendors provide APIs that expose specific functionalities and data points, enabling other applications to request information or trigger actions within the ERP system. This allows for dynamic, real-time data exchange. For example, a marketing automation tool might use an ERP API to pull customer contact information for targeted campaigns.

- Connectors and Adapters: These are pre-built or custom-developed components that bridge the gap between the ERP system and other applications. Connectors are often designed for specific popular applications (e.g., a Salesforce connector), simplifying the integration process. Adapters are more general-purpose and can be configured to map data fields and translation rules between systems.

- Enterprise Service Bus (ESB): In larger, more complex environments, an ESB can act as a central integration hub. It provides a standardized way for applications to connect and communicate, handling message routing, transformation, and orchestration of services. This promotes a more decoupled and scalable integration architecture.

The strategic use of these integration capabilities ensures that data flows efficiently across the organization, supporting better decision-making and automating cross-departmental workflows.

Data Security and Performance Optimization in ERP Environments

Managing data security and ensuring optimal performance are critical considerations for any ERP system, given the sensitive and vast amounts of data they handle. These aspects are deeply embedded in the architectural design and ongoing management of the system. Data Security: Protecting the integrity, confidentiality, and availability of business data is paramount. ERP systems employ a multi-layered approach to security.

- Access Control: Role-based access control (RBAC) is a fundamental security feature. Users are assigned specific roles, and each role has predefined permissions dictating what data they can view, edit, or delete. This prevents unauthorized access and ensures that users only interact with information relevant to their job function.

- Data Encryption: Data is often encrypted both in transit (when moving between the ERP system and users or other applications) and at rest (when stored in the database). This makes the data unreadable to unauthorized parties, even if they gain access to the underlying storage.

- Auditing and Logging: Comprehensive audit trails are maintained, recording all user activities, data modifications, and system events. This allows for the tracking of changes, identification of security breaches, and compliance with regulatory requirements.

- Regular Security Updates and Patching: ERP vendors and IT teams are responsible for applying security patches and updates regularly to address vulnerabilities and protect against emerging threats.

Performance Optimization: Ensuring that the ERP system operates efficiently and responds quickly to user requests is vital for productivity and user adoption.

- Database Tuning: This involves optimizing database queries, indexing strategies, and server configurations to ensure rapid data retrieval and processing. Poorly optimized databases are a common bottleneck for ERP performance.

- Application Server Configuration: Proper allocation of memory, processing power, and load balancing across application servers is crucial for handling peak user loads and complex transactions without slowdowns.

- Caching Mechanisms: Frequently accessed data or computed results can be stored in cache memory to reduce the need for repeated database queries, significantly speeding up response times.

- System Monitoring and Analytics: Continuous monitoring of system performance metrics (CPU usage, memory, network traffic, transaction times) helps identify potential issues before they impact users. Performance analytics provide insights into bottlenecks and areas for improvement.

- Hardware Infrastructure: The underlying hardware (servers, storage, network) must be adequately provisioned and maintained to support the demands of the ERP system.

A proactive approach to both security and performance is essential for maintaining a reliable and trustworthy ERP system that supports the ongoing success of the business.

Analyze the impact of enterprise resource planning systems on different industry sectors and business sizes.

Enterprise Resource Planning (ERP) systems are not one-size-fits-all solutions. Their profound impact on business operations is deeply intertwined with the specific demands of various industry sectors and the operational scale of organizations. Tailoring ERP functionalities to these unique contexts is crucial for maximizing efficiency, driving innovation, and maintaining a competitive edge. The inherent complexity and regulatory landscapes of different industries necessitate specialized ERP modules and configurations that address sector-specific workflows and compliance requirements.The adaptability of ERP solutions allows them to cater to a wide spectrum of business needs.

In manufacturing, ERP systems are indispensable for managing complex supply chains, production scheduling, inventory control, quality assurance, and bill of materials. They enable real-time tracking of raw materials, work-in-progress, and finished goods, minimizing waste and optimizing production cycles. For the retail sector, ERP integrates point-of-sale (POS) systems, inventory management across multiple channels, customer relationship management (CRM), and financial reporting. This integration is vital for understanding customer purchasing patterns, managing stock levels efficiently, and ensuring a seamless omnichannel experience.

The healthcare industry benefits from ERP systems that manage patient records, appointment scheduling, billing, inventory of medical supplies, and compliance with stringent regulations like HIPAA. This ensures efficient patient care delivery and robust data security. In the services sector, ERP solutions often focus on project management, resource allocation, time tracking, client billing, and service delivery optimization. They help service-based businesses manage their most valuable asset – their people – and ensure timely and profitable project completion.

ERP Needs and Implementation Approaches for SMEs vs. Large Corporations

The distinct characteristics of Small and Medium-sized Enterprises (SMEs) and large corporations lead to divergent ERP needs and implementation strategies. SMEs often seek ERP solutions that are cost-effective, user-friendly, and offer core functionalities to streamline essential business processes like accounting, inventory, and customer management. Their implementation approaches are typically more agile, with a focus on rapid deployment and minimal disruption.

Cloud-based ERP solutions are particularly popular among SMEs due to their lower upfront costs, scalability, and reduced IT infrastructure requirements. The emphasis is on achieving immediate operational improvements and gaining better visibility into their business.Large corporations, on the other hand, often require highly customized and complex ERP systems that can handle a vast volume of transactions, integrate with numerous legacy systems, and support intricate global operations.

Their implementation projects are usually extensive, involving significant investment in customization, integration, and change management. Large enterprises may opt for on-premises or hybrid ERP solutions to maintain greater control over their data and infrastructure. The strategic goals often extend beyond operational efficiency to include enterprise-wide digital transformation, advanced analytics, and global standardization of processes. The implementation timeline is considerably longer, and the focus is on achieving a comprehensive and integrated business management platform that can support long-term strategic objectives.

ERP Adoption’s Influence on Competitive Positioning and Market Responsiveness

The adoption of ERP systems significantly shapes an organization’s competitive positioning and its ability to respond to market dynamics. In sectors where agility and rapid adaptation are key, such as e-commerce or fast-moving consumer goods, ERP systems that provide real-time data analytics and supply chain visibility allow businesses to quickly adjust production, pricing, and marketing strategies in response to changing consumer demands or competitor actions.

For example, a retail company with an integrated ERP can swiftly reallocate inventory to high-demand regions or launch targeted promotions based on real-time sales data, thereby outmaneuvering less agile competitors.In more regulated industries like pharmaceuticals or aerospace, ERP systems that ensure strict adherence to quality control, compliance, and traceability enhance credibility and reduce the risk of costly errors or recalls.

This robust compliance framework becomes a competitive differentiator, assuring clients and regulatory bodies of the company’s reliability. Furthermore, by optimizing internal processes, ERP systems free up resources that can be redirected towards innovation, product development, or enhanced customer service, all of which contribute to a stronger market presence and sustained competitive advantage. The ability to access and analyze comprehensive business data through an ERP empowers leadership to make more informed strategic decisions, leading to improved market responsiveness and a proactive approach to industry challenges.

Trends and Innovations in ERP for Diverse Business Environments

The ERP landscape is constantly evolving to meet the dynamic needs of diverse business environments and organizational scales. A significant trend is the continued dominance of cloud-based ERP solutions, offering greater accessibility, scalability, and flexibility, which are particularly beneficial for SMEs and rapidly growing businesses. Artificial Intelligence (AI) and Machine Learning (ML) are increasingly being integrated into ERP systems, enabling advanced predictive analytics, automated decision-making, and intelligent process optimization.

For instance, AI can forecast demand with greater accuracy, optimize inventory levels to prevent stockouts, or even automate routine accounting tasks.Another key innovation is the rise of industry-specific ERP solutions, often referred to as “vertical ERPs.” These are pre-configured systems designed with the specific workflows, regulations, and terminologies of particular industries, significantly reducing the need for extensive customization. This allows businesses, regardless of size, to implement powerful ERP capabilities more quickly and cost-effectively.

The focus on user experience (UX) is also paramount, with modern ERP interfaces becoming more intuitive and mobile-friendly, enhancing user adoption and productivity across all levels of an organization. Furthermore, the emphasis on interoperability and open APIs is enabling ERP systems to seamlessly integrate with a wider ecosystem of specialized applications, creating a more connected and intelligent business environment.

Selecting and Implementing an Enterprise Resource Planning System Effectively

Embarking on the journey to select and implement an Enterprise Resource Planning (ERP) system is a significant undertaking for any business. It requires meticulous planning, strategic decision-making, and dedicated execution to ensure the chosen solution aligns with organizational goals and drives operational efficiency. This process is not merely about acquiring new software; it’s about transforming how a business operates, integrates its functions, and leverages data for informed decision-making.

A well-executed ERP implementation can lead to substantial improvements in productivity, cost savings, and competitive advantage, while a poorly managed one can result in significant financial losses and operational disruptions.The path to a successful ERP adoption involves several critical stages, each demanding careful attention and a structured approach. From understanding the unique needs of the organization to finally going live with the new system, every step plays a vital role in the overall outcome.

This section will guide businesses through the essential phases of selecting and implementing an ERP system, providing a roadmap for navigating this complex but rewarding process.

ERP System Selection: A Step-by-Step Guide

Choosing the right ERP solution is paramount to achieving the desired business outcomes. This involves a systematic approach to identify needs, evaluate options, and make an informed decision. Businesses should approach this selection process with clarity and a comprehensive understanding of their current and future requirements.

- Needs Assessment and Requirements Definition: The foundational step is to thoroughly analyze existing business processes, identify pain points, and define clear, measurable objectives for the ERP system. This involves engaging stakeholders from all departments to gather input on functional requirements, technical needs, and desired outcomes. Key areas to consider include finance, human resources, supply chain management, customer relationship management, and manufacturing. A detailed requirements document will serve as the benchmark for evaluating potential vendors.

- Market Research and Vendor Identification: Once requirements are defined, the next step is to research the ERP market and identify potential vendors that offer solutions aligning with the organization’s specific industry, size, and budget. This can involve consulting industry reports, attending trade shows, and seeking recommendations from peers. Create a longlist of vendors that appear to meet the basic criteria.

- Request for Proposal (RFP) and Vendor Evaluation: Develop a comprehensive Request for Proposal (RFP) document that Artikels the defined requirements, technical specifications, implementation expectations, and pricing models. Distribute the RFP to the shortlisted vendors. Evaluate the responses rigorously, focusing on functional fit, technological capabilities, vendor experience, implementation methodology, support services, and total cost of ownership.

- Demonstrations and Proof of Concept (POC): Invite the top-tier vendors to provide detailed demonstrations of their solutions, tailored to the organization’s specific use cases. For complex requirements, consider a Proof of Concept (POC) to test critical functionalities in a real-world scenario. This hands-on experience is invaluable for assessing usability and system performance.

- Reference Checks and Due Diligence: Contact existing customers of the finalist vendors to gather feedback on their implementation experiences, system performance, and ongoing support. Conduct thorough due diligence on the financial stability and long-term viability of the vendor.

- Negotiation and Contract Finalization: Once a preferred vendor is identified, engage in detailed negotiations regarding pricing, licensing, implementation services, support agreements, and service level agreements (SLAs). Ensure all terms are clearly documented and legally binding in the final contract.

ERP Implementation: Critical Phases

Implementing an ERP system is a complex project that requires careful management through distinct phases to ensure a smooth transition and successful adoption. Each phase builds upon the previous one, culminating in a fully operational system.

- Planning and Project Initiation: This initial phase involves establishing the project scope, objectives, budget, and timeline. A dedicated project team, including internal resources and external consultants, is formed. A detailed project plan is developed, outlining tasks, responsibilities, milestones, and communication strategies. This phase also includes setting up the project governance structure.

- System Design and Configuration: In this phase, the ERP system is configured to meet the specific business requirements identified during the selection process. This involves mapping business processes to system functionalities, defining workflows, and customizing reports. Data migration strategies are also planned and developed.

- Development and Customization (if applicable): If the chosen ERP system requires custom development or integration with other existing applications, this phase focuses on building and testing these components. This can include developing new modules, interfaces, or specific functionalities not available out-of-the-box.

- Data Migration: This critical step involves extracting, cleaning, transforming, and loading data from legacy systems into the new ERP system. Accurate and complete data migration is essential for the system’s integrity and user confidence.

- Testing: Rigorous testing is conducted throughout the implementation lifecycle. This includes unit testing (individual components), integration testing (interactions between modules), system testing (end-to-end processes), and user acceptance testing (UAT) where end-users validate the system against their requirements.

- Training: Comprehensive training programs are developed and delivered to all end-users. This ensures that employees are proficient in using the new system and understand how it impacts their daily tasks. Training should be role-specific and ongoing.

- Go-Live: This is the phase where the new ERP system is deployed and becomes operational. It typically involves a cutover period where the old system is retired and the new system takes over. Post-go-live support is crucial to address any immediate issues and ensure a smooth transition.

- Post-Implementation Review and Optimization: After the system is live, a review is conducted to assess the project’s success against its objectives. Continuous monitoring and optimization are performed to leverage the full capabilities of the ERP system and adapt to evolving business needs.

Best Practices for User Training and Change Management

Successful ERP adoption hinges on user buy-in and proficiency. Effective training and robust change management strategies are essential to overcome resistance and foster a positive user experience.

- Early and Continuous Communication: Keep all stakeholders informed about the project’s progress, benefits, and impact on their roles from the outset. Transparency builds trust and reduces anxiety.

- Involve Users in the Process: Engage end-users in requirements gathering, testing, and feedback sessions. This fosters a sense of ownership and ensures the system meets their practical needs.

- Tailored Training Programs: Develop training materials and sessions that are specific to each user’s role and responsibilities. Generic training can be overwhelming and ineffective.

- Hands-on Training and Practice Environments: Provide users with opportunities to practice using the system in a realistic, non-production environment. This builds confidence and reinforces learning.

- Train-the-Trainer Approach: Identify key individuals within departments to become system champions. Train them thoroughly, and they can then train their colleagues, providing localized support.

- Develop Comprehensive User Manuals and Support Resources: Create easily accessible documentation, FAQs, and quick reference guides. Establish a clear support channel for users to seek assistance.

- Acknowledge and Address Resistance: Understand that change can be difficult. Proactively identify potential areas of resistance and address concerns through open dialogue and by highlighting the benefits of the new system.

- Post-Go-Live Support and Reinforcement: Continue to provide support and refresher training after the system goes live. Monitor user adoption and identify areas where additional training or process adjustments may be needed.

- Celebrate Successes: Recognize and celebrate milestones and successful adoption. This reinforces positive behavior and motivates users.

Typical ERP Implementation Project Timeline

An ERP implementation project timeline can vary significantly based on the complexity of the business, the chosen ERP solution, and the implementation partner. However, a typical project can be broken down into distinct phases with key milestones.

| Phase | Duration (Months) | Key Milestones & Deliverables |

|---|---|---|

| Planning & Project Initiation | 1-3 | Project Charter, Detailed Project Plan, Project Team Established, Vendor Selection Complete |

| System Design & Configuration | 3-6 | Business Process Mapped, System Configuration Document, Data Migration Strategy |

| Development & Customization (if applicable) | 2-5 | Developed Customizations, Integration Interfaces Tested |

| Data Migration | 1-3 | Cleaned Data Sets, Successful Data Load into Test Environment |

| Testing | 2-4 | Unit Test Results, Integration Test Results, System Test Results, User Acceptance Testing (UAT) Sign-off |

| Training | 1-2 | Training Materials Developed, End-User Training Completed |

| Go-Live | 1-2 Weeks | System Deployed, Production Data Loaded, Go-Live Support Active |

| Post-Implementation Review & Optimization | Ongoing | Post-Go-Live Support, Performance Monitoring, Optimization Recommendations Implemented |

Investigating the Future Trajectory and Emerging Trends Shaping the Landscape of Enterprise Resource Planning

The world of Enterprise Resource Planning (ERP) is in constant flux, driven by technological innovation and evolving business demands. As businesses strive for greater agility, deeper insights, and more seamless operations, ERP systems are evolving to meet these challenges head-on. This section delves into the key trends and future directions that are poised to redefine what ERP can do for organizations of all sizes and across all industries.

Artificial Intelligence and Machine Learning Integration in ERP

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into ERP systems is rapidly transforming them from reactive data repositories into proactive, intelligent platforms. These advanced technologies are being leveraged to unlock unprecedented levels of predictive analytics and automation, fundamentally changing how businesses manage their operations. AI and ML algorithms can analyze vast datasets from across an organization’s various modules – finance, supply chain, human resources, and customer relationship management – to identify patterns, predict future outcomes, and even automate routine tasks.

For instance, in financial management, AI can forecast cash flow with greater accuracy by analyzing historical trends, economic indicators, and even social media sentiment. In supply chain, ML models can predict demand fluctuations, optimize inventory levels to minimize stockouts and overstocking, and identify potential disruptions before they occur. Predictive maintenance, powered by AI analyzing sensor data from manufacturing equipment, can anticipate failures, allowing for scheduled repairs and preventing costly downtime.

Automation extends to areas like invoice processing, where AI can read, classify, and enter invoices, significantly reducing manual effort and errors. Furthermore, AI-driven chatbots and virtual assistants are being embedded within ERP interfaces to provide employees with instant access to information and support, streamlining workflows and improving user experience. The continuous learning capabilities of ML ensure that these systems become more accurate and insightful over time, adapting to changing business conditions and providing ever-more sophisticated decision support.

This intelligent layer is moving ERP beyond simple transaction processing to a strategic partner in business growth and resilience.

The Growing Importance of IoT Integration in ERP

The Internet of Things (IoT) is fundamentally reshaping operational landscapes, and its integration with ERP systems is proving to be a game-changer, particularly in enhancing supply chain visibility and operational efficiency. By connecting physical devices, sensors, and machinery to the digital realm, IoT generates a continuous stream of real-time data. When this data is fed into an ERP system, it provides an unprecedented level of insight into the physical world.

In supply chain management, for example, IoT sensors embedded in shipping containers can track location, temperature, humidity, and shock, providing real-time updates on the condition and whereabouts of goods. This granular visibility allows businesses to proactively address potential issues, such as temperature excursions that could spoil sensitive products, or delays in transit. Furthermore, IoT-enabled asset tracking within warehouses and factories can provide precise inventory counts, optimize material flow, and monitor the utilization of equipment.

For manufacturers, connected machinery can transmit performance data, enabling predictive maintenance, reducing unplanned downtime, and optimizing production schedules. This real-time data integration allows ERP systems to move beyond historical reporting to dynamic, responsive management of operations. The potential for enhanced efficiency is immense, as businesses can identify bottlenecks, optimize resource allocation, and improve overall throughput based on actual, live conditions rather than delayed or estimated data.

The Shift Towards Subscription-Based Cloud ERP Models

The paradigm shift towards subscription-based cloud ERP models is profoundly influencing accessibility and scalability for businesses of all sizes. Historically, implementing and maintaining on-premises ERP systems was a significant capital investment, often prohibitive for small and medium-sized enterprises (SMEs). Cloud-based ERP, offered on a Software-as-a-Service (SaaS) model, democratizes access to powerful business management tools. Instead of large upfront costs for hardware, software licenses, and implementation, businesses pay a recurring subscription fee, which is typically based on usage or the number of users.

This predictable operational expense makes sophisticated ERP solutions attainable for a wider range of companies. Scalability is another key advantage. Cloud ERP systems can be easily scaled up or down to meet changing business needs. As a company grows, it can add more users, modules, or functionalities with relative ease, without the need for extensive hardware upgrades or complex reconfigurations.

Conversely, during leaner periods, businesses can scale back their usage, optimizing costs. This flexibility is crucial in today’s dynamic business environment. Furthermore, cloud ERP providers handle the infrastructure, maintenance, security, and updates, freeing up internal IT resources to focus on more strategic initiatives. This accessibility and agility are critical drivers for businesses looking to compete effectively in the global marketplace.

The Evolving Role of Data Analytics and Business Intelligence in ERP

The role of data analytics and business intelligence (BI) within ERP systems has evolved from basic reporting to becoming a cornerstone of informed strategic decision-making. Modern ERP systems are no longer just transactional engines; they are sophisticated data hubs that, when coupled with advanced analytics and BI tools, provide deep insights into every facet of an organization’s operations. This evolution allows businesses to move beyond simply knowing what happened to understanding why it happened and, more importantly, predicting what is likely to happen.

BI tools integrated with ERP can transform raw data into actionable intelligence through interactive dashboards, visual reports, and key performance indicators (KPIs). For example, a sales manager can quickly access real-time data on sales performance by region, product, or salesperson, identifying top performers and areas needing improvement. Financial analysts can leverage BI to conduct in-depth profitability analysis, forecast revenue, and manage budgets with greater precision.

In the supply chain, analytics can reveal trends in demand, supplier performance, and logistics costs, enabling optimization and risk mitigation. The true power lies in the ability to connect disparate data sources within the ERP – from finance to inventory to customer interactions – to uncover complex relationships and hidden opportunities. This comprehensive view empowers executives and managers to make more data-driven decisions, allocate resources more effectively, identify competitive advantages, and navigate market changes with greater confidence and agility.

Ultimate Conclusion

In essence, enterprise resource planning systems represent a critical strategic investment for any organization aiming for sustained success in today’s competitive landscape. By fostering integration, enhancing visibility, and enabling data-driven decision-making, ERP solutions empower businesses to not only optimize current operations but also to innovate and adapt to future challenges. The journey from initial concept to advanced, AI-driven platforms underscores the enduring value and evolving power of ERP in shaping the future of commerce.

Top FAQs

What is the primary goal of an ERP system?

The primary goal of an ERP system is to integrate and manage all core business processes across various departments into a single, unified system, thereby streamlining operations, improving efficiency, and providing a holistic view of the business.

How long does it typically take to implement an ERP system?

ERP implementation timelines can vary significantly, ranging from a few months for smaller, simpler systems to over a year or even longer for complex, enterprise-wide deployments. Factors like customization, data migration, and organizational readiness play a crucial role.

Can small businesses benefit from ERP?

Yes, small and medium-sized businesses (SMEs) can significantly benefit from ERP systems. Modern ERP solutions are often scalable and cloud-based, offering tailored functionalities that can help SMEs manage growth, improve efficiency, and compete more effectively.

What is the difference between ERP and CRM?

While both are business software, ERP focuses on integrating and managing internal business processes like finance, HR, and supply chain, whereas CRM (Customer Relationship Management) specifically focuses on managing customer interactions and sales processes.

Is an ERP system a one-time purchase?

For on-premises solutions, it is typically a one-time license purchase with ongoing maintenance fees. However, cloud-based ERP systems are usually offered on a subscription basis, involving recurring payments.