ERP system for supply chain management is crucial for modern businesses. This comprehensive guide delves into the foundational elements, critical functionalities, implementation processes, collaborative impacts, and future trends of these powerful systems. We will explore how an ERP system fundamentally integrates disparate supply chain functions, detailing core modules like procurement, inventory management, logistics, and manufacturing. The strategic advantages of centralizing supply chain data within a unified ERP framework are significant, offering a clearer picture of operations and enabling better decision-making.

Understanding the essential steps in assessing an organization’s specific supply chain needs is paramount before ERP selection. A comparative overview of different ERP deployment models, such as cloud, on-premises, and hybrid, will be presented, alongside their implications for supply chains. Furthermore, we will demonstrate a structured approach to vendor evaluation and software demonstrations, culminating in a procedural guide for successful ERP implementation, emphasizing change management and user training for supply chain personnel.

This exploration aims to provide a thorough understanding of how these systems can revolutionize supply chain operations.

Foundational Elements of an ERP System for Supply Chain Operations

An Enterprise Resource Planning (ERP) system designed for supply chain management is more than just a software solution; it’s a digital backbone that orchestrates the complex web of activities involved in bringing products from raw materials to the end consumer. At its core, such an ERP system aims to provide a single, unified view of all supply chain operations, breaking down traditional silos between departments and stakeholders.

This integration is paramount because a supply chain is inherently interconnected. A delay in procurement can halt production, an inventory miscalculation can lead to stockouts or excess, and inefficient logistics can significantly increase costs and reduce customer satisfaction. By bringing these functions under one umbrella, an ERP system allows for real-time data sharing, enhanced visibility, and improved decision-making across the entire supply chain.

It acts as a central nervous system, enabling proactive management rather than reactive firefighting.The fundamental integration of disparate supply chain functions within an ERP system is achieved through a shared database and standardized processes. Imagine a scenario without an ERP: procurement might use one system, inventory another, and sales a third. Data would be manually transferred, leading to errors, delays, and a lack of a single source of truth.

An ERP system eliminates this fragmentation. When a sales order is placed, the ERP immediately checks inventory levels. If stock is insufficient, it can automatically trigger a reorder or a production request. This seamless flow of information ensures that procurement is aware of upcoming needs, production schedules can be adjusted accordingly, and logistics can plan for timely shipments. The system can track goods from the moment they are ordered from a supplier, through their receipt, storage, transformation (if applicable), and final delivery to the customer.

This end-to-end visibility allows for the identification of bottlenecks, optimization of lead times, and a more agile response to market fluctuations. Furthermore, it facilitates better collaboration with suppliers and customers by providing them with relevant, albeit controlled, access to information, fostering stronger partnerships and a more resilient supply chain. The ability to forecast demand more accurately, based on historical sales data, production capacity, and market trends, is another significant outcome of this integrated approach.

This forecasting then informs procurement and production planning, minimizing the risk of both shortages and overstocking.

Core Modules in Supply Chain ERP Solutions

The efficacy of an ERP system in supply chain management hinges on the robust functionality of its core modules, each designed to address specific operational areas and contribute to the overall integrated ecosystem. These modules are not isolated entities but rather interconnected components that share data and workflows, enabling a holistic view and control over the supply chain.

- Procurement Management: This module handles all aspects of sourcing and purchasing raw materials, components, and finished goods. It typically includes functionalities for supplier management, purchase requisition and order processing, contract management, invoice matching, and spend analysis. Effective procurement ensures that the right materials are acquired at the right price and time, directly impacting production costs and availability. It also plays a crucial role in supplier relationship management, fostering collaboration and ensuring compliance with ethical sourcing standards.

- Inventory Management: Central to any supply chain, this module tracks the quantity, location, and status of all inventory items, from raw materials to work-in-progress and finished goods. Features often include stock level monitoring, cycle counting, warehouse management (including put-away, picking, and packing), demand forecasting integration, and inventory valuation. Accurate inventory management minimizes carrying costs, prevents stockouts that can disrupt sales, and reduces obsolescence.

- Logistics and Warehouse Management: This module oversees the movement and storage of goods throughout the supply chain. It encompasses transportation management (planning, execution, and optimization of shipping routes and carriers), warehouse operations (receiving, put-away, picking, packing, shipping, and inventory control within the warehouse), and potentially yard management. Efficient logistics ensures timely delivery, reduces transportation costs, and enhances customer satisfaction through reliable fulfillment.

- Manufacturing and Production Planning: For companies involved in production, this module is critical. It manages production scheduling, material requirements planning (MRP), capacity planning, shop floor control, bill of materials (BOM) management, and quality control. It ensures that production is aligned with demand, resources are utilized efficiently, and products are manufactured to specification, on time and within budget.

- Sales and Order Management: While often considered a sales function, this module is intrinsically linked to the supply chain. It manages customer orders from entry to fulfillment, including order processing, pricing, credit checks, and allocation of inventory. Real-time visibility into order status and inventory availability is crucial for providing accurate delivery estimates and managing customer expectations.

Strategic Advantages of Centralizing Supply Chain Data

Centralizing supply chain data within a unified ERP framework yields significant strategic advantages, transforming how businesses operate and compete. This consolidation moves away from fragmented, siloed information systems to a single, integrated platform, creating a robust foundation for operational excellence and informed strategic decision-making. The benefits are far-reaching, impacting efficiency, cost, agility, and overall profitability.One of the most immediate advantages is enhanced visibility.

When all supply chain data—from procurement orders and inventory levels to production schedules and shipment statuses—resides in one place, stakeholders gain a comprehensive, real-time view of operations. This end-to-end visibility allows for proactive identification of potential disruptions, such as a supplier delay or a sudden surge in demand. Instead of reacting to problems after they occur, businesses can anticipate them and take corrective actions, minimizing their impact.

For example, if inventory levels for a critical component drop unexpectedly, the procurement module can immediately alert production, and logistics can be informed to expedite a replacement shipment, preventing a costly production stoppage. This level of foresight is invaluable in today’s volatile market conditions.Furthermore, data centralization leads to improved operational efficiency and reduced costs. With a unified system, redundant data entry is eliminated, manual processes are streamlined, and workflows are automated.

This not only saves time and labor but also significantly reduces the risk of human error, which can be costly in supply chain operations. For instance, discrepancies in inventory counts due to manual errors can lead to overstocking, increasing carrying costs, or stockouts, resulting in lost sales and customer dissatisfaction. An ERP system, with its integrated inventory and sales modules, ensures data accuracy and consistency.

The ability to optimize inventory levels based on accurate demand forecasts and real-time sales data directly translates into reduced holding costs and improved cash flow. Similarly, optimized logistics planning, informed by real-time data on carrier availability, routes, and shipment volumes, can lead to substantial savings in transportation expenses.The strategic agility and responsiveness gained from centralized data are also critical. In a dynamic market, businesses need to adapt quickly to changing customer demands, economic shifts, and competitive pressures.

A unified ERP system provides the agility to do so. By having instant access to comprehensive data, management can make faster, more informed decisions regarding production adjustments, sourcing strategies, or distribution network changes. This agility allows companies to capitalize on new opportunities and navigate challenges more effectively. For instance, if market analysis indicates a growing demand for a particular product, the ERP system can quickly assess production capacity, raw material availability, and distribution capabilities, enabling a rapid ramp-up of production and fulfillment.

This responsiveness is a key differentiator in maintaining a competitive edge.

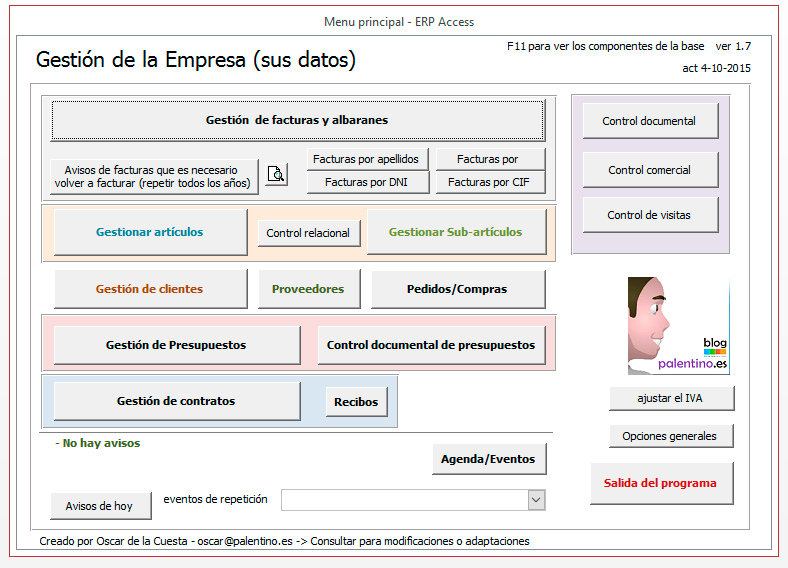

Conceptual Diagram of ERP Module and Partner Information Flow, Erp system for supply chain management

A conceptual diagram illustrating the flow of information between core ERP modules and external supply chain partners would depict a central ERP system acting as the nexus, with various internal modules communicating with each other and exchanging data with external entities. This diagram visually represents the interconnectedness and data flow that underpins an effective supply chain.At the heart of the diagram is the ERP system, represented as a central hub.

Radiating from this hub are the core internal modules: Procurement, Inventory Management, Manufacturing, Logistics, and Sales & Order Management. These modules are shown with bidirectional arrows connecting them, signifying the constant exchange of data. For example, the Sales & Order Management module sends order data to Inventory Management to check stock availability and to Manufacturing for production planning if stock is insufficient.

Procurement receives updated raw material needs from Manufacturing. Inventory Management provides stock level updates to both Sales and Manufacturing. Logistics receives shipping requirements from Sales and inventory data from Inventory Management.Surrounding this central ERP hub are the external supply chain partners. These typically include Suppliers, Customers, and Logistics Service Providers (LSPs) or Carriers. Arrows extend from the ERP modules to these external partners, and vice-versa, indicating data exchange.

Supplier Interaction:

- The Procurement module in the ERP sends purchase orders (POs) to Suppliers.

- Suppliers, in turn, send order confirmations, advance shipping notices (ASNs), and invoices back to the Procurement module.

- In some advanced setups, Suppliers might access a portal connected to the ERP to view POs and update shipment information directly.

Customer Interaction:

- The Sales & Order Management module sends order confirmations and shipping notifications to Customers.

- Customers might interact through a customer portal to place orders, track order status, or view invoices. This data then flows into the Sales & Order Management module.

Logistics Service Provider (LSP) / Carrier Interaction:

- The Logistics module sends shipment requests, including delivery details and required pick-up times, to LSPs/Carriers.

- LSPs/Carriers provide shipment tracking updates, proof of delivery (POD), and potentially freight invoices back to the Logistics module.

- This data from LSPs is crucial for updating the status of orders in the Sales & Order Management module and for inventory tracking within the Inventory Management module.

The arrows in the diagram would also show data flowing between these external entities, mediated by the ERP. For instance, an ASN from a supplier, received by Procurement, triggers an update in Inventory Management, which then informs Sales about incoming stock. The overall flow demonstrates how the ERP system acts as a central coordinator, ensuring that all parties have the necessary, up-to-date information to perform their roles effectively, leading to a synchronized and efficient supply chain.

This interconnectedness, visualized in the diagram, highlights the power of a unified ERP in managing complex supply chain dynamics.

Explore the critical functionalities that an ERP system must possess to optimize supply chain visibility and control.

An effectively implemented ERP system acts as the central nervous system for a supply chain, transforming fragmented data into actionable intelligence. It moves beyond mere record-keeping to empower organizations with the foresight and agility needed to navigate complex, dynamic environments. Achieving true supply chain optimization hinges on a suite of critical functionalities that provide unparalleled visibility and robust control over every stage of the process, from raw material procurement to final product delivery.

These functionalities are not isolated features but rather interconnected components that work in concert to drive efficiency, reduce costs, and enhance customer satisfaction.The power of an ERP in supply chain management lies in its ability to integrate disparate systems and data sources, creating a single, unified view of operations. This holistic perspective is fundamental to identifying bottlenecks, predicting disruptions, and making informed decisions.

Without this integrated approach, organizations are left operating in silos, reacting to problems rather than proactively managing them. The functionalities discussed below are essential for any organization serious about transforming its supply chain from a cost center into a strategic advantage.

Real-time Tracking and Tracing Capabilities

Real-time tracking and tracing capabilities within an ERP system are absolutely paramount for enhancing operational awareness across the entire supply chain. Imagine a scenario where a critical component for a manufacturing process is delayed at an international port. Without real-time visibility, the production manager might only discover this issue when the raw materials fail to arrive on schedule, leading to costly downtime and missed delivery deadlines.

An ERP system equipped with robust tracking and tracing features, however, provides immediate notification of the delay. This allows for proactive adjustments, such as expediting alternative shipments, reallocating resources, or informing affected customers of potential delays. This granular level of insight extends beyond just shipments; it can encompass the location and status of inventory at various nodes – in transit, in warehouses, or on the production floor.Furthermore, this capability is invaluable for quality control and regulatory compliance.

For instance, in the pharmaceutical or food industries, the ability to trace a product’s journey from its origin through every handling point is not just a matter of efficiency but a critical requirement for safety and recall management. If a batch of products is found to be defective or contaminated, the ERP system can instantly pinpoint its location, facilitating a swift and targeted recall, thereby minimizing public health risks and protecting brand reputation.

The data captured through these tracking mechanisms, often integrated with technologies like RFID, GPS, and barcode scanning, paints a dynamic picture of the supply chain. This constant flow of information allows for the identification of patterns, such as consistently late carriers or problematic transit routes, which can then be addressed through strategic vendor management or route optimization. The operational awareness fostered by real-time tracking and tracing empowers decision-makers to move from a reactive stance to a predictive and preventive one, significantly reducing uncertainty and improving overall supply chain resilience.

It transforms the supply chain from a series of disconnected events into a transparent, controllable continuum.

Demand Forecasting and Planning Modules

Demand forecasting and planning modules within an ERP system are indispensable for enabling proactive supply chain management. Instead of simply reacting to current orders, these modules leverage historical data, market trends, seasonality, and even external factors like economic indicators or promotional activities to predict future demand with a greater degree of accuracy. This predictive power is the cornerstone of efficient inventory management.

By understanding anticipated demand, businesses can optimize their inventory levels, ensuring they have enough stock to meet customer needs without incurring excessive holding costs or risking obsolescence. For example, a retail company can use an ERP’s forecasting module to predict the demand for seasonal items like winter coats. Based on this forecast, they can place orders with suppliers well in advance, secure favorable pricing, and ensure sufficient warehouse space is allocated, thus avoiding stockouts during peak season and overstocking after the season ends.Moreover, these planning modules facilitate sophisticated production scheduling and resource allocation.

Armed with demand forecasts, manufacturers can plan their production runs more effectively, aligning output with anticipated sales. This prevents the inefficient practice of producing goods speculatively, which can lead to wasted resources and capital tied up in unsold inventory. The ERP system can then translate these production plans into detailed requirements for raw materials and components, automatically generating purchase orders or requisitions to ensure timely replenishment.

This integrated approach minimizes the bullwhip effect, a phenomenon where small fluctuations in demand at the retail level become amplified as they move up the supply chain, leading to significant inefficiencies and stock imbalances. The proactive nature of these modules also extends to logistics planning. By anticipating shipping volumes, companies can negotiate better rates with carriers, optimize delivery routes, and ensure sufficient transportation capacity is available, thereby reducing shipping costs and improving delivery times.

In essence, demand forecasting and planning modules transform the supply chain from a reactive system driven by immediate orders into a strategically orchestrated operation that anticipates and prepares for future needs.

Proactive Risk Mitigation and Exception Management

An ERP system significantly facilitates proactive risk mitigation and exception management across the supply chain by providing the tools and insights necessary to identify potential issues before they escalate and to respond swiftly when deviations occur. Risk mitigation starts with visibility; understanding where potential vulnerabilities lie is the first step to addressing them. For instance, if an ERP system tracks supplier performance and identifies a particular supplier consistently missing delivery deadlines or providing sub-standard materials, this information can trigger a proactive risk assessment.

The system can then prompt managers to explore alternative suppliers, diversify the supplier base, or work with the existing supplier to implement corrective actions, thereby mitigating the risk of production delays or quality issues stemming from that source.Exception management is where the ERP system truly shines in its ability to handle unforeseen events. An exception might be a sudden surge in demand that outstrips current inventory, a natural disaster affecting a key transportation route, or a quality control failure at a manufacturing plant.

When such an event occurs, the ERP system can be configured to automatically flag it as an exception. For example, if an inventory level for a critical component drops below a pre-defined safety stock threshold due to unexpected demand, the ERP can automatically generate an urgent replenishment order and alert the procurement team. Similarly, if a shipment is rerouted due to a port closure, the ERP can recalculate estimated delivery times, update inventory records, and notify affected downstream stakeholders.

This automated alerting and workflow management ensures that critical issues are not overlooked and are addressed promptly by the responsible parties. Consider a scenario where a customs delay is encountered for an inbound shipment. The ERP system, integrated with customs brokerage data, can flag this delay, estimate the new arrival time, and automatically notify the production planning team, allowing them to adjust the manufacturing schedule accordingly.

This proactive approach prevents minor disruptions from cascading into major crises, ensuring business continuity and maintaining customer trust.

Performance Metrics and Key Indicators for Continuous Improvement

The leverage of performance metrics and key indicators (KPIs) through an ERP system is fundamental to achieving continuous improvement in supply chain operations. An ERP system acts as a central repository for vast amounts of operational data, which can then be analyzed and presented in the form of meaningful metrics and KPIs. These indicators provide a clear, data-driven picture of how well the supply chain is performing against established goals and benchmarks.

Without this structured measurement, improvements would be based on intuition rather than evidence, making it difficult to identify areas for optimization or to gauge the effectiveness of implemented changes.For example, an ERP system can track and report on critical KPIs such as:

- On-Time Delivery Rate: This metric measures the percentage of orders delivered to customers by the promised date. A consistently high on-time delivery rate indicates an efficient and reliable supply chain.

- Inventory Turnover Ratio: This KPI shows how many times inventory is sold and replaced over a period. A higher turnover ratio generally suggests efficient inventory management and less capital tied up in stock.

- Order Cycle Time: This measures the average time it takes from when a customer places an order to when it is delivered. Reducing order cycle time leads to faster fulfillment and improved customer satisfaction.

- Perfect Order Rate: This is a comprehensive metric that assesses orders delivered on time, complete, undamaged, and with accurate documentation. It provides a holistic view of order fulfillment quality.

- Supplier Performance Metrics: This includes tracking lead times, quality defect rates, and on-time delivery from individual suppliers, enabling better supplier selection and management.

The ERP system facilitates the regular monitoring of these KPIs, often through customizable dashboards and automated reports. By visualizing trends over time, managers can identify areas where performance is slipping or excelling. For instance, a declining on-time delivery rate might prompt an investigation into transportation efficiency, warehouse operations, or supplier reliability. Conversely, a significant improvement in inventory turnover could highlight the success of new inventory management strategies.

This continuous feedback loop, powered by ERP-generated data, allows organizations to make informed decisions, refine processes, and allocate resources effectively. It transforms the supply chain from a static operational model into a dynamic, evolving system that is constantly being measured, analyzed, and improved. The ability to benchmark performance against industry standards or historical data further fuels this improvement cycle, ensuring the supply chain remains competitive and responsive to market demands.

Selecting and Implementing an ERP System for Supply Chain Management

Embarking on the journey to select and implement an Enterprise Resource Planning (ERP) system for supply chain management is a significant undertaking. It requires meticulous planning, a deep understanding of current needs, and a strategic approach to integration. This process is not merely about acquiring new software; it’s about transforming how an organization operates its supply chain, aiming for enhanced efficiency, visibility, and responsiveness.

The following sections delve into the critical stages of this transformative process, from initial assessment to successful deployment.

Assessing Organization-Specific Supply Chain Needs

Before any software vendor is even contacted, a thorough assessment of an organization’s unique supply chain needs is paramount. This foundational step ensures that the chosen ERP system will genuinely address existing pain points and align with strategic objectives. Without this due diligence, the risk of selecting an ill-fitting system, leading to costly rework or outright failure, increases significantly. The assessment should involve cross-functional teams, including representatives from procurement, logistics, manufacturing, warehousing, sales, and finance, to capture a holistic view of the supply chain ecosystem.The process begins with a detailed mapping of current supply chain processes.

This involves documenting every step, from raw material sourcing and supplier management to production, inventory control, order fulfillment, and final delivery. Key performance indicators (KPIs) for each stage should be identified and baseline data collected. This provides a clear picture of current performance and highlights areas ripe for improvement. For instance, if lead times are consistently missed, the assessment needs to pinpoint whether the bottleneck lies in procurement, production scheduling, or transportation.Furthermore, identifying existing challenges and inefficiencies is crucial.

This could include issues like a lack of real-time inventory visibility, manual data entry errors, poor demand forecasting accuracy, or difficulties in tracking shipments. Understanding these pain points helps define the functional requirements for the ERP system. For example, if inaccurate inventory levels are a recurring problem, the ERP must offer robust inventory management modules with real-time tracking capabilities.It’s also vital to consider the organization’s future growth and strategic direction.

Will the company be expanding into new markets, introducing new product lines, or adopting new business models? The ERP system should be scalable and flexible enough to accommodate these future changes. This might involve assessing the need for multi-currency support, localization features, or advanced analytics for future market analysis.Finally, a comprehensive needs assessment involves understanding the technological landscape. What existing systems need to be integrated with the ERP?

Are there any specific hardware or infrastructure requirements? This foresight prevents integration headaches down the line. For example, if the company relies heavily on a legacy warehouse management system, the ERP must offer seamless integration capabilities with that system to avoid data silos and manual data transfer. This detailed, multi-faceted assessment forms the bedrock upon which the entire ERP selection and implementation process is built.

Comparative Overview of ERP Deployment Models for Supply Chains

The choice of ERP deployment model significantly impacts how a supply chain management system functions, its cost, and its flexibility. Organizations must carefully consider these models against their specific operational needs, IT capabilities, and budget constraints. Each model offers distinct advantages and disadvantages, and the optimal choice often hinges on a strategic balance of these factors.

- On-Premises Deployment: In this traditional model, the ERP software is installed and run on the company’s own servers and IT infrastructure, located within the organization’s physical premises. This offers the highest degree of control over data security and customization. For supply chains that handle highly sensitive proprietary data or operate in heavily regulated industries, the absolute control offered by on-premises solutions can be a significant advantage.

However, it requires substantial upfront investment in hardware, software licenses, and ongoing maintenance, including IT staff for system management and updates. The responsibility for system uptime, security patches, and disaster recovery rests entirely with the organization. For supply chains where agility and rapid scaling are paramount, on-premises can sometimes be slower to adapt to new demands due to the need for physical infrastructure upgrades.

- Cloud Deployment (SaaS – Software as a Service): Cloud-based ERP solutions are hosted by a third-party vendor and accessed by users over the internet. This model eliminates the need for significant upfront hardware investment and reduces the burden of IT maintenance, as the vendor manages infrastructure, software updates, and security. Cloud ERPs are typically subscription-based, offering predictable operational expenses. This model fosters agility, allowing organizations to scale resources up or down quickly in response to fluctuating supply chain demands, such as seasonal peaks or sudden market shifts.

Real-time data access from anywhere with an internet connection is a major boon for globally dispersed supply chain teams. However, it means relinquishing some control over data location and security to the vendor, and reliance on internet connectivity is absolute. Customization options may also be more limited compared to on-premises solutions, though modern SaaS platforms are increasingly offering robust configuration tools.

- Hybrid Deployment: A hybrid approach combines elements of both on-premises and cloud deployments. This model allows organizations to host certain sensitive or critical applications on-premises while leveraging the cloud for other functions, such as CRM or collaboration tools. For supply chains, this could mean keeping core inventory and manufacturing execution systems on-premises for maximum control, while using a cloud-based transportation management system for external logistics partners.

This model offers a balance between control, flexibility, and cost. It allows organizations to migrate to the cloud gradually or to maintain specific functionalities on-site for compliance or performance reasons. The complexity lies in managing integrations between the on-premises and cloud components, requiring careful IT planning and expertise.

Each deployment model has direct implications for supply chain operations. Cloud solutions often provide superior real-time visibility and collaboration capabilities across a distributed network, crucial for modern, agile supply chains. On-premises offers a robust, secure environment for tightly controlled processes, while hybrid solutions provide a pragmatic path for organizations with diverse needs and existing infrastructure investments.

Structured Approach to Vendor Evaluation and Software Demonstration

Selecting the right ERP vendor and solution is a critical juncture that demands a structured and objective evaluation process. This ensures that the chosen software not only meets current functional requirements but also aligns with the organization’s long-term vision and that the vendor is a reliable partner. A systematic approach minimizes risks and maximizes the chances of a successful implementation.The process typically begins with developing a comprehensive Request for Proposal (RFP).

This document should clearly Artikel the organization’s identified supply chain needs, functional requirements, technical specifications, integration needs, budget constraints, and implementation timeline. The RFP serves as a standardized document for vendors to respond to, allowing for direct comparison of their offerings.Once RFPs are sent out, a shortlist of potential vendors is compiled based on their initial responses, industry reputation, financial stability, and demonstrated experience in supply chain ERP implementations.

For each shortlisted vendor, a structured software demonstration is essential. These demonstrations should not be generic sales pitches; they must be tailored to the organization’s specific use cases and workflows. This means providing vendors with detailed scenarios that reflect the company’s day-to-day operations and challenges.During the demonstration, a scoring matrix should be used to objectively evaluate how well the ERP system addresses each requirement.

Key areas to focus on include:

- Functional Fit: Does the software perform the essential supply chain functions required, such as demand planning, inventory management, order processing, warehouse management, and transportation management, to the organization’s satisfaction?

- User Interface and Ease of Use: How intuitive is the system? Will supply chain personnel be able to learn and use it efficiently with minimal training?

- Integration Capabilities: Can the ERP seamlessly integrate with existing systems (e.g., CRM, WMS, TMS, accounting software) without significant custom development?

- Reporting and Analytics: Does the system provide robust reporting tools and dashboards for real-time visibility into supply chain performance and for data-driven decision-making?

- Scalability and Flexibility: Can the system grow with the organization and adapt to future changes in business processes or market demands?

- Vendor Support and Implementation Methodology: What level of support does the vendor offer during and after implementation? What is their proven implementation methodology?

It is also advisable to request references from the vendor’s existing clients, particularly those in a similar industry or with similar supply chain complexities. Speaking with these references provides invaluable insights into the vendor’s track record, the actual implementation experience, and the long-term performance of the software.Beyond the formal demonstration, consider requesting a proof-of-concept or a trial period for the most promising solutions.

This allows key users to interact with the system in a more hands-on manner, providing practical feedback. A structured vendor evaluation, encompassing a detailed RFP, tailored demonstrations, objective scoring, and reference checks, is fundamental to making an informed decision that sets the stage for a successful ERP implementation.

Procedural Framework for Successful ERP Implementation

A successful ERP implementation for supply chain management is a complex project that requires a structured, phased approach, with a strong emphasis on managing change and empowering users. The goal is to transition smoothly from existing systems and processes to the new ERP, ensuring minimal disruption to operations and maximizing the return on investment. This procedural framework Artikels the key steps involved in achieving this objective.The implementation process typically begins with a dedicated project kickoff meeting, bringing together the project team, key stakeholders, and the implementation partner.

This meeting establishes clear project goals, scope, roles, responsibilities, and communication protocols. A detailed project plan is then developed, outlining all phases, tasks, timelines, and resource allocation. This plan should be a living document, subject to regular review and updates.One of the most critical phases is system configuration and customization. This involves tailoring the ERP software to align with the organization’s specific supply chain processes and business rules.

It’s crucial to strike a balance between necessary customization and adhering to standard functionalities to avoid over-complication and future upgrade challenges. Data migration is another pivotal step. This involves extracting, cleansing, transforming, and loading data from legacy systems into the new ERP. Inaccurate or incomplete data can cripple the new system, so meticulous data validation is essential.

“Data integrity is the bedrock of an effective ERP system; without it, even the most sophisticated software will fail to deliver its promised value.”

Crucially, a robust change management strategy must be integrated throughout the implementation. This involves proactive communication to all affected employees about the upcoming changes, the benefits of the new system, and how it will impact their roles. Identifying potential resistance points and developing strategies to address them is key. This might include establishing a change champions network within departments to advocate for the new system and provide peer support.User training is an indispensable component of successful adoption.

Training programs should be tailored to different user roles and responsibilities, covering specific modules and functionalities they will use. Training should be hands-on, practical, and delivered in a timely manner, ideally close to the go-live date. Post-go-live support is also vital. This includes help desks, on-site support, and readily available documentation to assist users as they navigate the new system.The implementation then progresses through rigorous testing phases, including unit testing, integration testing, and user acceptance testing (UAT).

UAT is particularly important, as it involves end-users validating that the system meets their operational needs and performs as expected in real-world scenarios.Finally, the go-live phase marks the transition to the new ERP system. This should be carefully planned, often with a phased rollout approach to minimize risk. Post-implementation, a period of stabilization and optimization follows, where the system’s performance is monitored, and any lingering issues are addressed.

Continuous improvement should be an ongoing effort, with regular reviews of system usage and identification of opportunities for further optimization. This structured approach, with change management and user training at its core, ensures that the ERP system becomes a valuable asset, driving efficiency and control across the supply chain.

The Transformative Impact of ERP on Collaborative Supply Chain Networks

An enterprise resource planning (ERP) system acts as the central nervous system for modern businesses, and its influence extends far beyond internal operations, profoundly transforming how supply chains collaborate. By breaking down silos and creating a unified platform for data and processes, ERP systems enable unprecedented levels of connectivity and cooperation across extended supply chain networks. This integration fosters a more agile, responsive, and resilient supply chain, capable of navigating the complexities of today’s global marketplace.

The shift from linear, transactional relationships to dynamic, collaborative partnerships is a direct consequence of ERP’s ability to synchronize information and orchestrate activities across multiple entities.

Fostering Seamless Communication and Data Exchange with Supply Chain Partners

An ERP system fundamentally redefines how businesses communicate and exchange data with their external partners, such as suppliers and logistics providers. Before ERP, this often involved fragmented communication channels like emails, faxes, phone calls, and disparate spreadsheets, leading to delays, errors, and a lack of real-time visibility. An integrated ERP solution centralizes critical information, making it accessible and shareable in a controlled and secure manner.

For suppliers, this means they can receive purchase orders directly through the ERP, confirm availability, update lead times, and even submit invoices electronically, all within a standardized digital workflow. This eliminates manual data entry and reduces the potential for misinterpretation. Similarly, logistics providers can receive shipment notifications, update tracking information, and confirm delivery status directly into the ERP. This real-time data flow allows for proactive management of inventory, transportation, and potential disruptions.

The ERP acts as a single source of truth, ensuring that all parties are working with the most current and accurate information. This shared visibility reduces the need for constant back-and-forth communication and allows for quicker decision-making. For instance, a supplier can instantly see updated demand forecasts, enabling them to adjust production schedules accordingly, thereby preventing stockouts or excess inventory.

Likewise, a logistics provider can reroute shipments based on real-time traffic or weather conditions reported through the ERP, minimizing delays and associated costs. The ability to integrate with Electronic Data Interchange (EDI) standards further enhances this seamless exchange, allowing for automated transactions with partners who may not have direct access to the company’s ERP but can still participate in the digital ecosystem.

Enabling Collaborative Planning, Forecasting, and Replenishment (CPFR) Initiatives

Collaborative Planning, Forecasting, and Replenishment (CPFR) is a business process that leverages the knowledge and insights of trading partners to improve forecasting accuracy and inventory management. An ERP system is the technological backbone that makes robust CPFR initiatives possible by providing the necessary platform for shared data and synchronized processes. The core of CPFR involves joint forecasting, where the buyer and seller collaborate to create a unified demand forecast.

An ERP system facilitates this by allowing the buyer to share anonymized or aggregated sales data and promotional plans directly with suppliers. Suppliers, in turn, can contribute their own production capacities, lead times, and market intelligence. The ERP then aggregates this information, potentially using advanced analytics and machine learning algorithms, to generate a more accurate consensus forecast than either party could achieve alone.

This shared forecast then informs replenishment strategies. The ERP can automatically trigger replenishment orders based on this collaborative forecast and predefined inventory parameters, ensuring that the right products are available at the right time and place. Furthermore, the ERP system enables continuous monitoring and exception management. If actual sales deviate significantly from the forecast, the ERP can flag these discrepancies to both parties, prompting a joint review and adjustment of plans.

This iterative process, supported by the ERP’s real-time data capabilities, allows for rapid response to market changes and consumer demand fluctuations. For example, a major retailer using an ERP can share point-of-sale data with its key manufacturers. The ERP can then integrate this data with the manufacturer’s production schedules and inventory levels, leading to a collaborative forecast that minimizes stockouts during peak seasons and reduces excess inventory during lulls.

This symbiotic relationship, facilitated by the ERP, leads to optimized inventory levels, reduced waste, and improved customer satisfaction across the entire supply chain.

Streamlining Procurement and Inbound Logistics with Integrated Supplier Portals

Integrated supplier portals, powered by ERP systems, revolutionize procurement and inbound logistics by providing a centralized, digital gateway for all supplier interactions. These portals act as a one-stop shop, offering suppliers a self-service environment to manage their engagement with the company. From the moment a purchase requisition is initiated within the ERP, it can trigger notifications to the supplier portal, allowing potential suppliers to view tender documents, submit bids, and respond to requests for quotation (RFQs) electronically.

Once a purchase order is issued, it’s automatically pushed to the supplier portal, where the supplier can confirm receipt, acknowledge delivery dates, and even upload shipping documents like packing lists and bills of lading. This eliminates the need for manual order entry and confirmation, significantly reducing the risk of errors and delays. For inbound logistics, the portal provides real-time visibility into incoming shipments.

As goods are dispatched, suppliers can update their status in the portal, allowing the receiving company’s ERP to anticipate arrival times. This enables better planning for warehouse operations, labor allocation, and dock scheduling. Upon arrival, the received goods can be scanned and matched against the electronic packing list and purchase order directly within the ERP, facilitating faster goods receipt and payment processing.

Concrete examples include a large automotive manufacturer using an ERP-powered supplier portal. When a new part is needed, the ERP generates an RFQ, which is sent to approved suppliers via the portal. Suppliers submit their bids electronically, and the ERP’s procurement module analyzes them based on predefined criteria. Once an order is placed, the supplier receives it electronically, confirms lead times, and uploads shipping details.

The ERP then uses this information to schedule inbound logistics, ensuring that the parts arrive just in time for production. This streamlined process reduces lead times, minimizes administrative overhead, and improves the accuracy of inventory records, ultimately contributing to a more efficient and cost-effective supply chain.

Benefits of Enhanced Transparency and Trust in Extended Supply Chain Partnerships

The implementation of an ERP system cultivates enhanced transparency and trust within extended supply chain partnerships, leading to more robust and resilient relationships. By providing a shared, single source of truth for critical data, ERP systems demystify processes that were once opaque. Suppliers gain insight into demand patterns, production schedules, and payment statuses, fostering a sense of partnership rather than a purely transactional relationship.

This transparency allows suppliers to proactively manage their own resources and production, leading to more reliable delivery performance. Similarly, logistics providers benefit from clear visibility into shipment volumes, delivery windows, and performance metrics. This clarity enables them to optimize their own operations and allocate resources more effectively. The trust that develops from this transparency is invaluable. When all parties have access to the same accurate information, disputes are minimized, and collaborative problem-solving becomes the norm.

For instance, if a delay occurs, all partners can see the cause and work together to mitigate its impact, rather than engaging in finger-pointing. This shared understanding and commitment to open communication build a foundation of trust that is essential for navigating unpredictable market conditions and unexpected disruptions. The ability to track goods in real-time, monitor supplier performance against agreed-upon metrics, and ensure timely payments through an integrated ERP system reinforces this trust.

Over time, this cultivated trust leads to stronger, more collaborative partnerships, where businesses are more willing to share sensitive information, invest in joint initiatives, and support each other through challenging periods. This enhanced collaboration ultimately translates into a more agile, efficient, and competitive supply chain for all involved.

Uncover the advanced capabilities and future trends in enterprise resource planning for supply chain management.: Erp System For Supply Chain Management

As the supply chain landscape continues to evolve at an unprecedented pace, driven by technological advancements and shifting global dynamics, ERP systems are no longer just about managing core operations. They are becoming sophisticated platforms that leverage cutting-edge technologies to offer predictive insights, enhance security, and foster greater agility. This section delves into the advanced functionalities and emerging trends that are shaping the future of ERP in supply chain management, moving beyond foundational elements to explore truly transformative capabilities.

Artificial Intelligence and Machine Learning Integration for Predictive Supply Chain Analytics

The integration of Artificial Intelligence (AI) and Machine Learning (ML) into ERP systems is revolutionizing supply chain management by enabling predictive analytics. These technologies move beyond reactive problem-solving to proactive decision-making, allowing businesses to anticipate disruptions, optimize inventory levels, and forecast demand with remarkable accuracy. AI algorithms can process vast amounts of historical data, external market indicators, and real-time operational information to identify patterns and predict future outcomes.

For instance, ML models can analyze past sales data, promotional activities, economic trends, and even weather patterns to generate highly precise demand forecasts. This predictive capability helps in reducing stockouts and overstocking, thereby optimizing working capital and minimizing waste.Furthermore, AI-powered systems can predict potential supply chain disruptions, such as supplier delays, transportation issues, or geopolitical events, by monitoring news feeds, social media, and other unstructured data sources.

This allows supply chain managers to take preemptive measures, such as identifying alternative suppliers or rerouting shipments, before a disruption significantly impacts operations. Predictive maintenance is another key application, where ML algorithms analyze sensor data from machinery and vehicles to predict equipment failures, enabling scheduled maintenance and preventing costly downtime. In essence, AI and ML transform ERP systems from data repositories into intelligent engines that drive strategic supply chain decisions, enhancing efficiency, resilience, and profitability.

Blockchain Technology for Enhanced Supply Chain Security and Traceability

Blockchain technology is emerging as a critical component in modern ERP solutions, significantly bolstering supply chain security and traceability. At its core, blockchain is a distributed, immutable ledger that records transactions across a network of computers. Each transaction, once added, cannot be altered or deleted, creating a transparent and tamper-proof record of all supply chain activities. This inherent security feature is invaluable for tracking the provenance of goods, verifying their authenticity, and ensuring compliance with regulatory requirements.By integrating blockchain with ERP systems, companies can create a single, shared source of truth for all stakeholders involved in the supply chain, from raw material suppliers to end consumers.

This eliminates information silos and reduces the risk of fraud, counterfeiting, and unauthorized product diversion. For example, in the pharmaceutical industry, blockchain can be used to track drugs from manufacturing to patient, ensuring they are genuine and have been stored under correct conditions throughout their journey. Similarly, in the food industry, it allows for rapid identification of the source of contamination in case of an outbreak, significantly reducing the scope of recalls.

The immutability of blockchain records also simplifies audits and dispute resolution, as all parties have access to an indisputable history of events. This enhanced transparency and trust fostered by blockchain technology are crucial for building robust and reliable supply chains in an increasingly complex global marketplace.

Internet of Things (IoT) Devices and Sensors for Real-Time Operational Data

The proliferation of Internet of Things (IoT) devices and sensors is fundamentally changing how ERP systems interact with the physical supply chain. These interconnected devices, embedded in everything from warehouse machinery and delivery trucks to individual products, continuously collect and transmit real-time operational data. This influx of granular, up-to-the-minute information provides an unprecedented level of visibility into the entire supply chain, enabling dynamic adjustments and immediate responses to changing conditions.For instance, sensors on warehouse shelves can monitor inventory levels in real-time, automatically triggering reorder alerts within the ERP system when stock falls below a predefined threshold.

Temperature and humidity sensors within refrigerated trucks can ensure that perishable goods are transported under optimal conditions, with alerts sent to the ERP if deviations occur, allowing for corrective actions to be taken before product quality is compromised. GPS trackers on vehicles provide real-time location data, enabling accurate estimated times of arrival (ETAs) and facilitating dynamic route optimization in response to traffic or other unforeseen events.

This constant stream of data allows ERP systems to move beyond periodic updates to a truly live operational environment. By feeding this data into the ERP, companies can gain immediate insights into production bottlenecks, logistics inefficiencies, and asset utilization, empowering them to make swift, data-driven decisions that optimize performance, reduce costs, and enhance customer satisfaction.

Evolving Landscape: Sustainability, Circular Economy, and Resilience in Supply Chain ERP

The contemporary supply chain ERP landscape is increasingly shaped by a growing emphasis on sustainability, the principles of a circular economy, and the imperative for enhanced resilience. These factors are not merely ethical considerations but are becoming critical business drivers that necessitate a strategic evolution of ERP functionalities. Sustainability, for instance, demands that ERP systems track and manage environmental impact across the entire supply chain.

This includes monitoring carbon emissions from transportation, energy consumption in manufacturing, and waste generation. ERPs are evolving to incorporate modules that can measure, report, and analyze these metrics, helping companies set and achieve sustainability goals.The concept of a circular economy, which focuses on minimizing waste and maximizing resource utilization through reuse, repair, and recycling, also requires significant ERP adaptation. ERP systems are being enhanced to manage reverse logistics, track product lifecycles for refurbishment and remanufacturing, and facilitate the efficient management of returned or end-of-life products.

This involves sophisticated inventory management for spare parts, detailed product genealogy for repair processes, and integration with platforms that facilitate material recovery. Furthermore, the heightened awareness of supply chain vulnerabilities, underscored by recent global events, has made resilience a paramount concern. ERP systems are being developed to support scenario planning and risk assessment, enabling businesses to identify potential chokepoints, diversify sourcing strategies, and build contingency plans.

This involves features that map out supplier dependencies, simulate the impact of various disruptions, and facilitate rapid switching to alternative suppliers or logistics routes. The integration of these principles into ERP systems is crucial for building supply chains that are not only efficient and profitable but also environmentally responsible, adaptable, and capable of withstanding future uncertainties.

Concluding Remarks

In essence, an ERP system for supply chain management is not merely a software solution; it’s a transformative strategy that enhances visibility, fosters collaboration, and drives efficiency across the entire supply chain. From foundational integration and critical functionalities to strategic selection and implementation, and finally to advanced capabilities and future trends, the journey with ERP promises a more resilient, agile, and profitable supply chain.

By embracing these systems, businesses can navigate the complexities of global commerce with greater confidence and achieve sustainable growth.

FAQ Overview

What are the primary benefits of using an ERP system for supply chain management?

The primary benefits include enhanced visibility across the supply chain, improved inventory accuracy, streamlined procurement processes, better demand forecasting, reduced operational costs, and increased overall efficiency and responsiveness to market changes.

How does an ERP system improve inventory management in a supply chain?

An ERP system provides real-time tracking of inventory levels, automates stock replenishment, optimizes stock levels to prevent stockouts or overstocking, and integrates with sales and production data to ensure accurate inventory counts and efficient movement of goods.

Can an ERP system help in managing supply chain risks?

Yes, ERP systems facilitate risk management by providing real-time data for proactive identification of potential disruptions, enabling scenario planning, and offering tools for exception management and quick response to unforeseen events.

What is the role of an ERP system in fostering collaboration with supply chain partners?

ERP systems enable seamless data exchange and communication with suppliers, logistics providers, and customers through features like supplier portals and integrated communication platforms, facilitating collaborative planning, forecasting, and order fulfillment.

How do advanced features like AI and IoT impact ERP for supply chain management?

AI and machine learning enhance predictive analytics for better forecasting and optimization, while IoT devices provide real-time operational data for dynamic adjustments, leading to more intelligent and responsive supply chain operations.